Originating from the Japanese words “kai” (change) and “zen” (good), Kaizen is a concept deeply embedded in Japanese business philosophy. It emerged post-World War II, to rebuild Japanese industries. Kaizen emphasizes gradual, incremental improvements to processes and products, fostering a culture of continuous enhancement. In the contemporary business landscape, kaizen has transcended its cultural origins and become a global phenomenon. It represents an ongoing commitment to improvement at all organizational levels. It translates perfectly into modern project management where small, manageable changes accumulate over time, resulting in substantial improvements. Its adaptability makes it applicable across various industries and sectors. This approach fosters a sense of responsibility and pride in one’s work, aligning personal and organizational goals for mutual success. Understanding the Kaizen Principles

The core principles of kaizen are based on continuous improvement, elimination of waste, standardization, and employee involvement. These principles form the foundation for creating a culture of sustained enhancement within an organization.

What is ‘kaizen’ lean?

Kaizen may be rooted in ancient traditions, but it shares many similarities with modern lean methodologies. ‘Kaizen lean’ focuses on minimizing waste, improving efficiency, and maximizing value for customers. The integration of kaizen principles enhances lean strategies by fostering a culture of continuous improvement, making processes leaner over time. The 10 Kaizen Principles

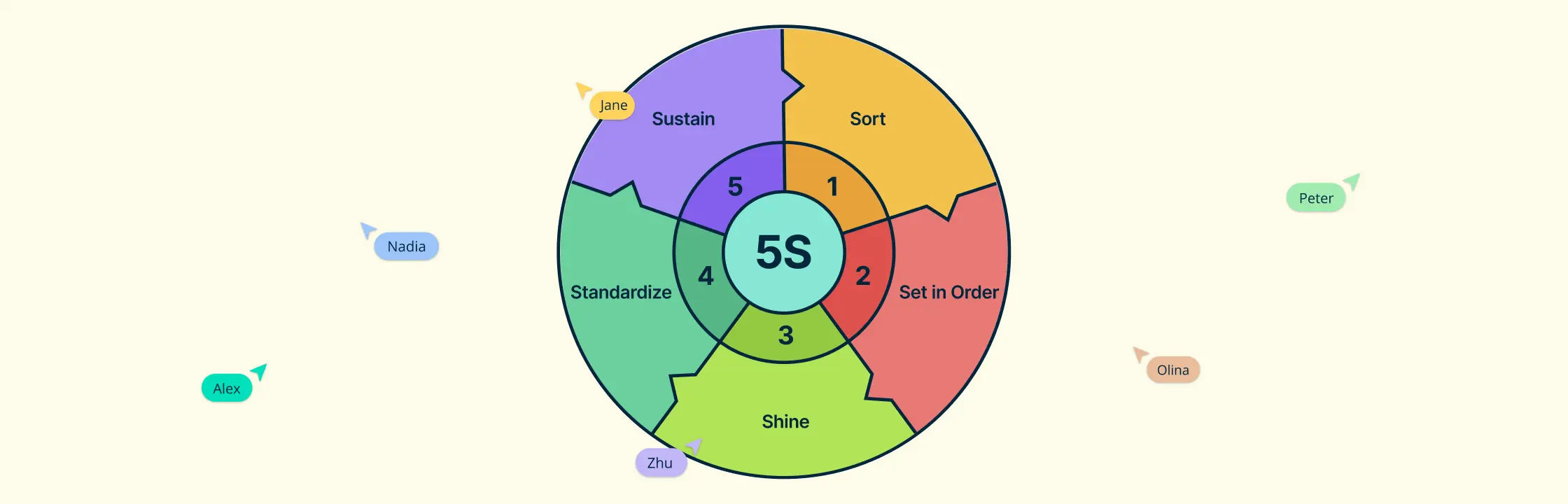

Seiri (Sort): Eliminate Unnecessary Items Seiri, the principle of sorting, revolves around identifying and eliminating unnecessary items in the workplace. The goal is to retain only essential items, promoting efficiency and reducing clutter. Regular assessments of workspaces help identify redundant tools, materials, or equipment. Prioritizing items based on relevance and frequency of use, and streamlining inventory management systems, contribute to increased workspace efficiency, improved safety, and better resource utilization.

Seiton (Set in Order): Organize the Workplace for Efficiency Seiton, or setting in order, focuses on organizing the workplace to optimize efficiency by assigning specific locations for tools, equipment, and materials. Designating areas based on the frequency of use, implementing visual cues for easy identification, and standardizing storage practices reduce search time, enhance workplace safety, and boost employee satisfaction with organized workspaces.

Seiso (Shine): Keep the Workplace Clean Seiso, emphasizing cleanliness, involves maintaining a clean and organized workplace through regular cleaning and inspection. Establishing routine cleaning schedules, encouraging employee responsibility for their work areas, and implementing visual management tools contribute to improved aesthetics, early issue identification, and prevention of equipment malfunctions due to cleanliness.

Seiketsu (Standardize): Establish Standardized Processes Seiketsu aims to create standardized processes and procedures to maintain consistency and efficiency. Documenting and communicating standardized work procedures, implementing training programs, and continuously reviewing and updating processes contribute to consistent output, easier training of new employees, and improved accountability in processes.

Shitsuke (Sustain): Maintain and Continually Improve Standards Shitsuke, the principle of sustaining improvements, focuses on maintaining gains and continually improving standards. Establishing a culture of discipline and accountability, encouraging regular audits, and actively involving employees in suggesting improvements contribute to long-term sustainability, a proactive organizational culture, and adaptability to evolving challenges.

Genchi Genbutsu (Go and See): Understand the Situation Firsthand Genchi Genbutsu encourages leaders and team members to go to the actual location where work is done to understand the situation firsthand. “Gemba walks”, encouraging people to go to where the problem is, and using real-time data contribute to an improved understanding of operational challenges, enhanced communication, and quick issue identification and resolution.

Kaizen Kozan (Continuous Improvement): Make Incremental Improvements Regularly Kaizen Kozan, the core principle of continuous improvement, emphasizes making small, incremental changes regularly. Establishing a systematic approach for collecting improvement ideas, encouraging employee participation, and celebrating small wins contribute to adaptability, increased innovation, and cumulative positive impact over time.

Teamwork: Foster Collaboration and Shared Responsibility Teamwork in kaizen emphasizes collaboration and shared responsibility among team members. Creating cross-functional teams, establishing clear communication channels, and fostering a culture of mutual support contribute to diverse problem-solving, improved morale, and increased accountability.

Personal Discipline: Encourage Individual Commitment to Improvement Personal Discipline in kaizen emphasizes individual commitment to adhering to standards and actively seeking ways to improve. Providing training on the importance of personal discipline, fostering a sense of ownership, and recognizing individuals who demonstrate discipline contribute to consistency, self-motivation, and alignment of individual goals with organizational objectives.

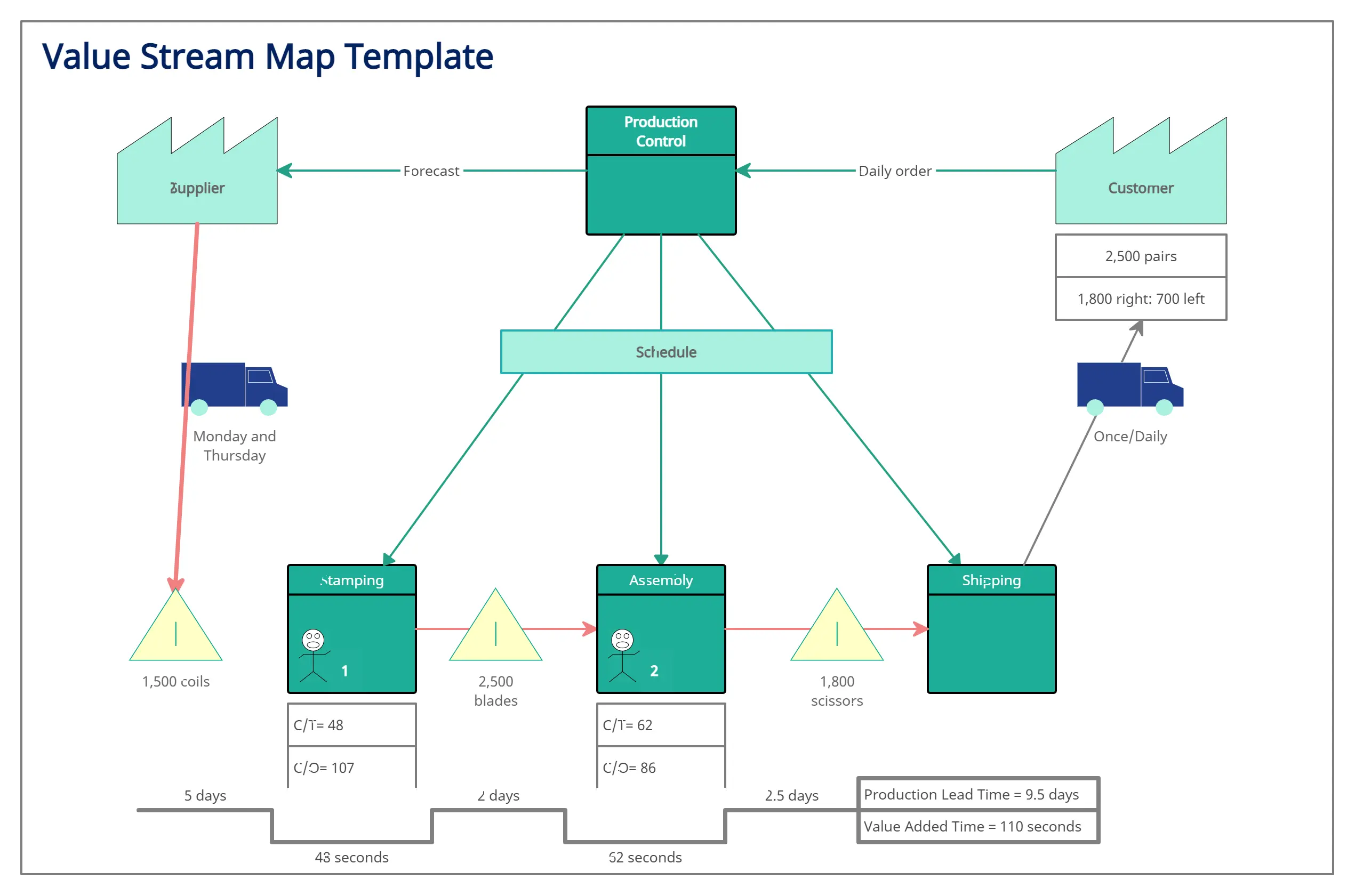

Muda (Waste Elimination): Identify and Eliminate All Forms of Waste Muda focuses on identifying and eliminating any form of waste, including time, resources, and materials. Conducting value stream mapping, implementing lean practices, and encouraging employees to suggest waste elimination contribute to increased efficiency, cost reduction, and improved overall process effectiveness. These ten kaizen principles collectively form a powerful framework for organizations seeking continuous improvement and excellence in their operations. Each principle, when applied strategically, contributes to a culture of innovation, efficiency, and sustained success.

The Benefits of The Kaizen Principles:

Waste Elimination: Lean principles, inspired by Kaizen, emphasize identifying and eliminating different forms of waste, known as “Muda” in Japanese. This includes overproduction, excess inventory, unnecessary motion, waiting time, defects, and underutilized talent. By eliminating waste, organizations can streamline processes and enhance overall efficiency.

Value Stream Mapping: Lean encourages the use of value stream mapping to analyze, visualize, and optimize the flow of materials and information throughout a process. This helps organizations identify areas of improvement and eliminate non-value-added activities.

Pull System: Kaizen principles are based on a pull system to produce items or deliver services based on actual customer demand. This contrasts with a push system where items are produced in anticipation of demand. The pull system minimizes overproduction and reduces inventory.

Just-in-Time (JIT) Production: Kaizen promotes the concept of producing only what is needed, when it is needed, and in the quantity needed. JIT reduces excess inventory, minimizes storage costs, and improves overall production efficiency.

5S Methodology: The 5S methodology is a set of practices aimed at creating and maintaining an organized, clean, and efficient workplace. The five pillars of 5S are Sort, Set in Order, Shine, Standardize, and Sustain – aligning with Kaizen principles.

Visual Management: Kaizen principles share Lean’s reliance on visual tools and techniques to make information easily accessible and understandable. Visual management helps teams monitor processes, identify issues, and track performance in real-time.

Respect for People: Central to both Kaizen and Lean is the respect for people within the organization. This involves recognizing and leveraging the skills, creativity, and insights of employees at all levels. Engaging and empowering employees is seen as essential for successful Lean implementation

Integrating Kaizen into Business Processes: A Structured Approach

Assessment: Identify Areas for Improvement The initial step involves a thorough assessment of existing processes. Scrutinize workflows, identify bottlenecks, and involve employees at all levels to gather diverse insights. This comprehensive data forms the foundation for targeted improvements.

Employee Involvement: Encourage Input from All Levels Kaizen places a strong emphasis on involving employees. Encourage open communication and actively seek input from employees at all levels. Frontline workers often possess valuable insights into operational challenges and can contribute ideas for improvement.

Planning: Develop a Roadmap for Implementation Developing a comprehensive roadmap is crucial for successful implementation. Prioritize improvement initiatives, set clear objectives, and establish a timeline. Consider resource allocation, potential challenges, and strategies for overcoming obstacles.

Implementation: Execute Small Changes Incrementally Rather than large-scale transformations, focus on executing small, manageable improvements. This collaborative effort involves cross-functional teams working together to implement planned improvements. The iterative nature enables quick adjustments based on real-time feedback.

Monitoring: Regularly Assess Progress and Adjust Strategies Continuous monitoring and assessment are integral. Regularly evaluate progress against objectives, measure key performance indicators, and gather feedback. Adjust strategies as needed based on results and identify new areas for improvement.

Kaizen has evolved into a global phenomenon, seamlessly integrating into modern project management. The ten principles, from eliminating unnecessary items to fostering collaboration and shared responsibility, form a powerful framework for innovation and sustained success. By systematically applying Kaizen, businesses can create a culture of responsibility, pride, and ongoing improvement, aligning personal and organizational goals for mutual prosperity in the dynamic landscape of today’s business world.