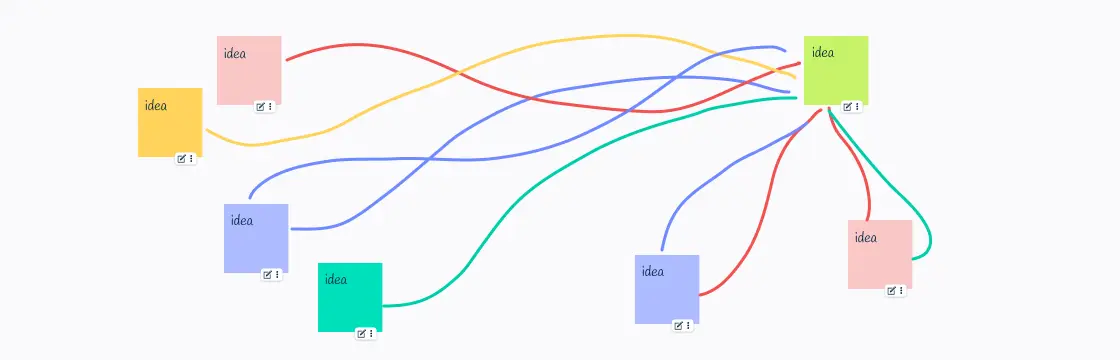

What is a Spaghetti Diagram?

A spaghetti diagram is a visual representation that maps out the physical flow of work in a process, highlighting the paths taken by workers, products, and information. It’s a tool that helps identify inefficiencies and areas for improvement by tracing the actual routes and distances covered within a workspace. The primary goal of a spaghetti diagram is to streamline workflows by reducing unnecessary movements and creating a more efficient layout.

The name itself is derived from the tangled appearance of these pathways, resembling a plate of spaghetti. By tracing the flow, a spaghetti diagram reveals the physical layout’s impact on work efficiency. It can uncover the hidden costs of inefficient layouts, such as excessive travel time between workstations, which may not be apparent at first glance. The visual nature of the diagram allows for a clear and immediate understanding of how space is utilized, making it an effective communication tool for stakeholders to discuss and strategize improvements.

The spaghetti diagram has its roots in the Lean Six Sigma methodology, specifically within the DMAIC (Define, Measure, Analyze, Improve, Control) approach. It’s designed to measure and analyze workflows, paving the way for significant process improvements and efficiency gains. Try our spaghetti diagram example today to maximize efficiency

Components of a Spaghetti Diagram

Workers: Tracks the movement of individuals within the space.

Products: Follows the path products take through the production or service delivery process.

Information Flow: Visualizes how information is communicated and transferred.

By understanding these components, organizations can create an effective flow to optimize delivery times and save time and money. For a deeper dive into process mapping, check out this process mapping guide.

Top Five Use Cases for Spaghetti Diagrams in Various Industries

Manufacturing Process Optimization

In manufacturing, every second and movement counts. By identifying inefficiencies in the production line, teams can reconfigure layouts to minimize unnecessary movement, leading to a more streamlined process. This not only enhances productivity but also contributes to a safer work environment. For instance, using a spaghetti diagram to reorganize a factory floor could result in a more logical sequence of operations, as highlighted in the production and manufacturing planning guides.

Service Delivery Streamlining

In the service sector, such as healthcare and hospitality, the spaghetti diagram helps in creating a seamless service delivery experience. By analyzing the flow of service staff and the delivery of services to customers, organizations can reduce wait times and improve overall customer satisfaction. For example, a hospital might use a spaghetti diagram to reduce the distance nurses travel between patients, thereby increasing the time they can spend on patient care.

Retail and Warehousing Layout Optimization

Retailers and warehouse managers can use spaghetti diagrams to optimize the layout of their spaces, ensuring that products are easily accessible and that the flow of goods from the stockroom to the sales floor is as efficient as possible. This can lead to faster stocking and retrieval times, which is crucial in a fast-paced retail environment. The spaghetti diagram can also help in avoiding bottlenecks in processes, ensuring a smooth operation during peak hours.

Logistics and Transportation Route Enhancement

For the logistics and transportation industry, the spaghetti diagram helps enhance routes and reduce travel time. By visualizing the most frequently traveled paths, companies can identify shortcuts and reduce fuel consumption, leading to significant cost savings and a reduced carbon footprint.

Office Layout and Information Flow Improvement

You can also use spaghetti diagrams to improve office layouts to foster better communication and information flow. By mapping out the physical movements of employees, companies can rearrange workstations to facilitate collaboration and reduce the time spent moving around the office. This not only improves efficiency but also enhances employee satisfaction, as they spend less time on unnecessary tasks and more on productive work.

The Advantages of Implementing a Spaghetti Diagram in Your Operations

Identifying Inefficiencies and Wastage

Optimizing Delivery Times and Flow

Cost Savings and Efficiency Gains

Continuous Improvement and Lean Management

Data-Driven Decision Making

When to Use a Spaghetti Diagram for Maximum Impact

Initial Process Analysis and Setup

When you’re at the drawing board, conceptualizing a new process or workspace layout, a spaghetti diagram can serve as an invaluable tool. It helps you visualize the flow of work and identify potential inefficiencies before they become embedded in your operations.

Scaling Operations and Maintaining Efficiency

As your business grows, processes that once seemed streamlined may begin to show signs of strain. Utilizing a spaghetti diagram during scaling can help maintain efficiency, ensuring that the increase in volume doesn’t lead to a proportional increase in waste or complexity.

Post-Implementation Reviews

After implementing a new system or layout, it’s crucial to review its effectiveness. A spaghetti diagram provides a clear, visual representation of the new workflow, allowing for easy comparison with the pre-implementation state.

Pre-Audit Process Validation

Before undergoing audits or reviews, it’s essential to validate your processes. A spaghetti diagram can help ensure that every step of your workflow is accounted for and optimized, providing a strong foundation for any external evaluation.

Step-by-Step Guide to Create Your Own Spaghetti Diagram

Here’s a step-by-step guide to help you create your spaghetti diagram.

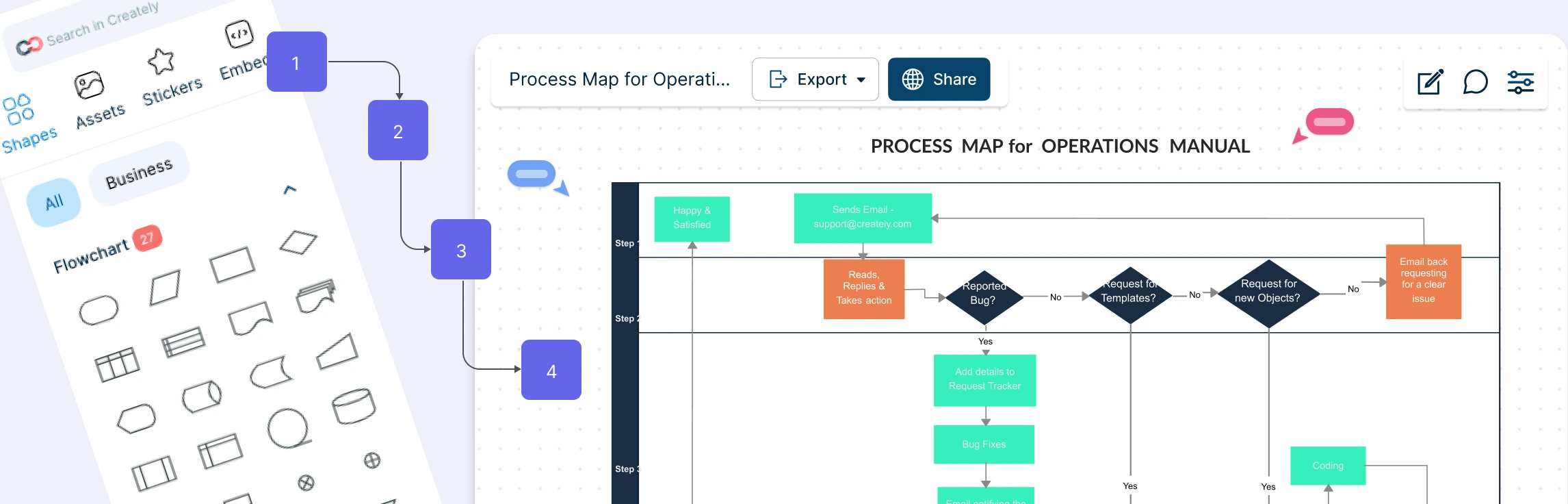

Map the Current State

Start by sketching the physical layout of the workspace. This will serve as the foundation of your spaghetti diagram. Creately features an infinite canvas to draw the areas where work is performed, and mark the key locations such as workstations, storage areas, and equipment.

Track Movements and Flows

Next, track the movement of people, products, and information. Observe the actual flow and use different connector types and colored lines to represent each type of movement. This will help you visualize where the flow is smooth and where it gets tangled like spaghetti—hence the name. Remember to include the flow of information, which is often overlooked but equally important.

Add Insights with the Notes Panel

As you map out the flows, use the notes panel to add observations or data about specific points in the process. This could include details like the time taken for a task, reasons for delays, or any other relevant information that can inform improvements.

Refine Your Spaghetti Diagram

Once the initial diagram is complete, review it for clarity and accuracy. Involve team members for feedback and make iterations as necessary. Look for patterns of inefficiency and consider how the layout could be rearranged to streamline the flow. Use the diagram to facilitate discussions on potential changes and to decide on the best course of action.

Tips for Creating an Effective Spaghetti Diagram

Make Sure Your Data is Accurate

Begin by gathering precise data on the movements and interactions within your process. Use tools Creately’s visual project management & execution tools to track the flow of work and ensure that every detail is accounted for. This accuracy is crucial for identifying true inefficiencies.

Get Cross-Functional Teams Involved

Involving team members from different departments can provide diverse perspectives on the process. This collaborative approach allows team members to contribute in real-time, ensuring a comprehensive view of the workflow.

Keep the Diagram Simple

While detail is important, a spaghetti diagram should not be overly complex. Keep it simple to allow for easy interpretation and to ensure that it can be understood at a glance.

Revise and Update Regularly

Processes evolve, and so should your spaghetti diagram. Regularly revisiting and updating your diagram ensures that it remains relevant and reflects the current state of your workflow.

Wrapping Up

The real power of a spaghetti diagram is in its ability to turn abstract data into actionable insights. By leveraging tools like Creately, teams can dynamically create and adjust their diagrams, ensuring they remain relevant and reflective of the current state of operations, thus embodying the principle of continuous improvement.

By following these tips and utilizing the right tools, you can create a spaghetti diagram that not only identifies inefficiencies but also paves the way for a more streamlined and efficient workflow. Remember, the goal is to visualize the flow of workers, products, and information in a way that highlights opportunities for optimization.